Products

Fm-107 sealant is a solvent-free, two-component polyurethane sealant

Five Advantages Of Products

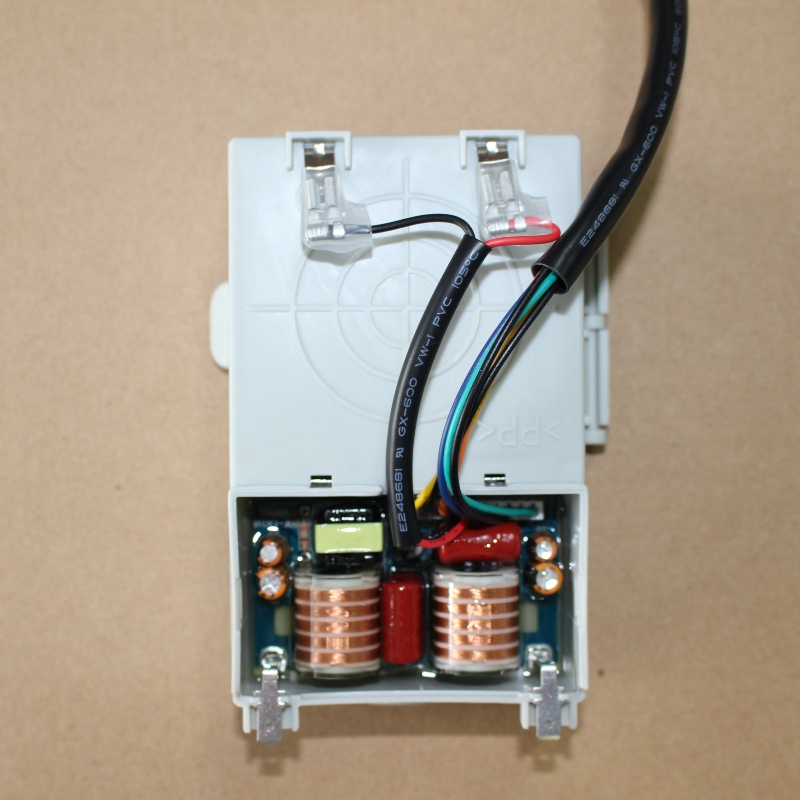

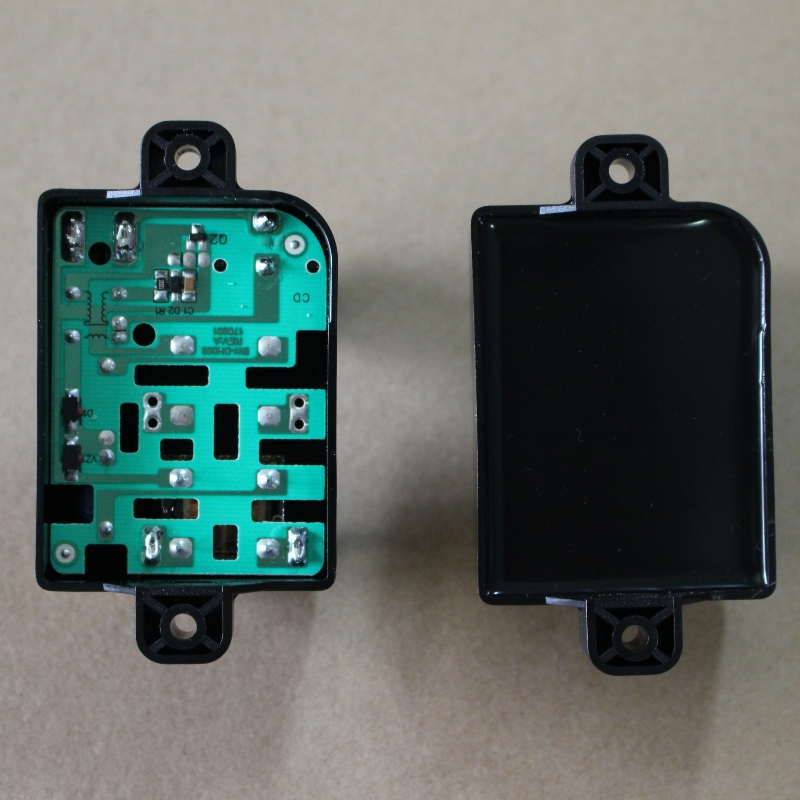

- It has excellent impact resistance and weather resistance. It is suitable for insulation, packaging and protection of electronic components.

- It is characterized by low hardness, moderate strength, good elasticity, water resistance, mould proof, shock proof and transparent.

- It has excellent electrical insulation and fire resistance.

- It has good adhesion to steel, aluminum, copper, tin, rubber, plastic and wood materials.

- The potting materials can make the installed and debugged electronic components and circuits free from vibration, corrosion, moisture and dust.

Product Details

1. Product introduction:

Fm-107 sealant is a solvent-free, two-component polyurethane sealant.

Soft and peeling repair

Shock proof and flame retardant

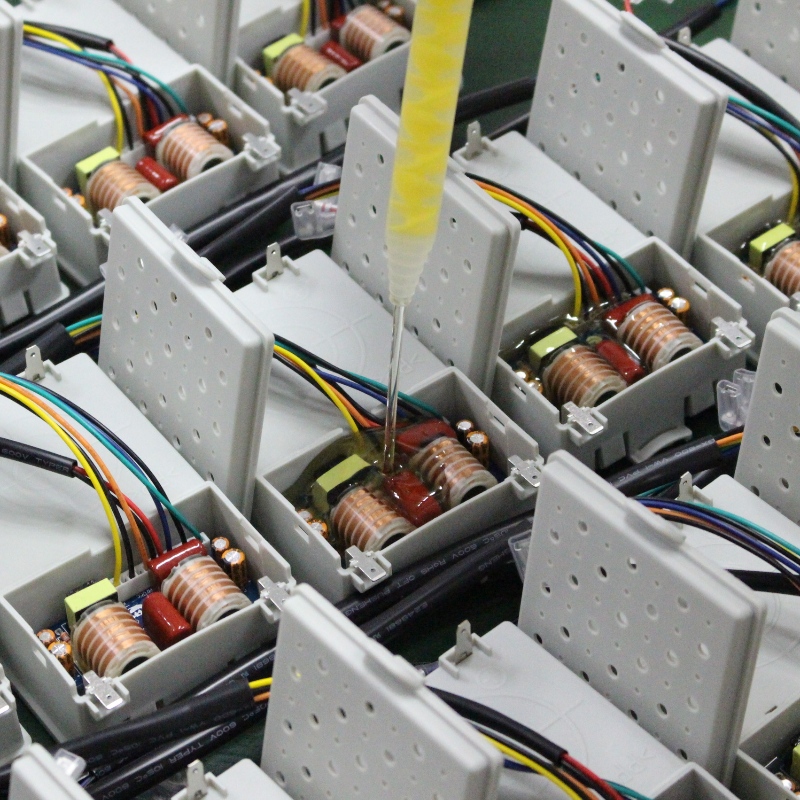

2. Application fields:

It is suitable for all kinds of circuit boards, such as washing machine fuzzy controller, electric bicycle drive controller, pulse igniter, etc.

3. Product performance parameters:

1. Properties before curing:

Item test method or condition component a component B

Visual inspection light yellow liquid

Viscosity: MPa · s, 1050 ± 200 ± 600 ± 200 at 23 ℃

Density: g / cm3, 23 ℃ 1.22 ± 0.05 0.99 ± 0.05

Shelf life: sealed at room temperature for half a year

2. Characteristics after curing:

Project unit or condition fm-107

The hardness is 35 ± 10

Tensile strength MPa ≥ 0.4

Elongation at break% ≥ 60

The volume resistivity is Ω· cm, 23 ℃ 2.6 × 1013

Insulation strength: kV / mm, 23 ℃ ≥ 17.0

Flame retardant vertical combustion V-2

Operating temperature range ℃ - 60 - 120

4.Process parameters:

Project unit or condition fm-107

Mixing ratio: weight ratio (A: b) 125:100

The operating time is min, 23 ℃ ≤ 5

Surface drying time: min, 23 ℃ ≤ 25

5.Package specification:

Material a is packed in iron drums, 20kg / iron drums (conventional); 25kg / PE drums (non-standard packaging)

Material B is packed in iron drums, 16KG / iron drums (conventional); 20kg / PE drums (non-standard packaging)

6.Precautions:

1. Components a and B should be sealed and stored. If they are not used up after opening, please seal them again.

2. In the process of glue filling, the mixing container and mixing tools should be kept away from water and moisture.

3. In the process of use, the dripping glue can be cleaned with acetone, ethyl acetate, dichloromethane and other solvents, but the solvent can not be mixed into unused a, B glue and potted glue.

Note: the above performance parameters are the typical data of the product tested at the humidity of 70% and temperature of 23 ℃. It is only for the reference of customers when using, and can not guarantee all the data that can be achieved in a specific environment. Please refer to the measured data when using.

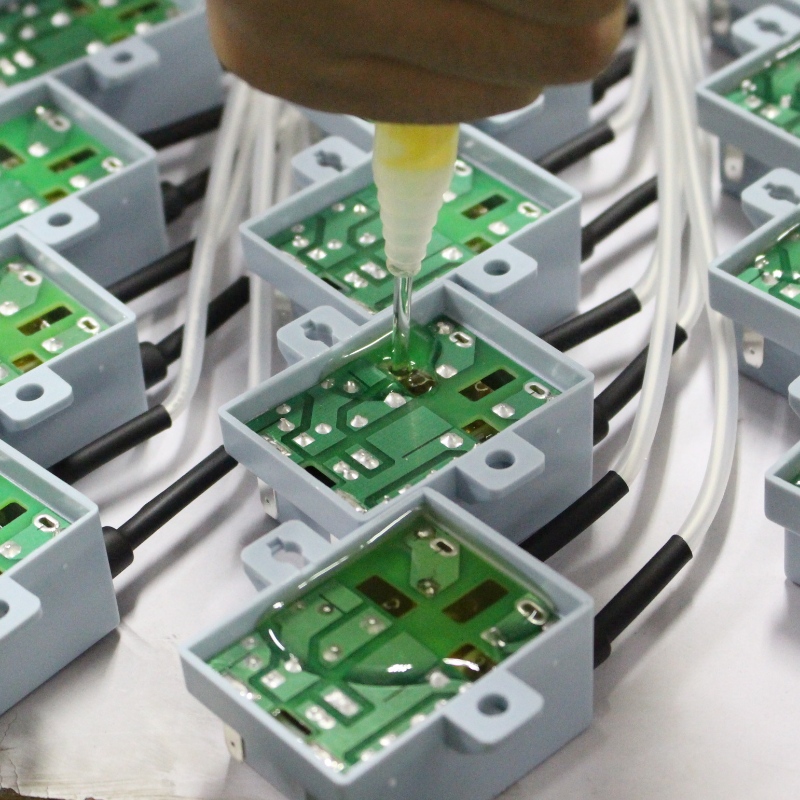

Manual use process:

1. Weigh components a and B according to the weight ratio a: B = 125:100 and put them into a clean mixing container

2. Use a clean mixing tool to stir evenly, and pay attention to scrape off the single component on the bottom and side wall of the container

3. After mixing, vacuumize

4. Curing at room temperature after pouring

Dongguan fuming sealing material Co., Ltd

Contact Person: Lu Yanting

Department: Marketing Department

Post: manager

Landline: +86 0769-85235661

Company Address: Nanzha No.4 Industrial Park, Humen Town, Dongguan City, Guangdong Province

Factory Address: Nanzha No.4 Industrial Park, Humen Town, Dongguan City, Guangdong Province

Website: fuming.us764.com

Previous: FM-500 (6) - 12 polyurethane pour...

Next: No