Products

FM-500 (6) - 12 polyurethane pouring sealant

Five Advantages Of Products

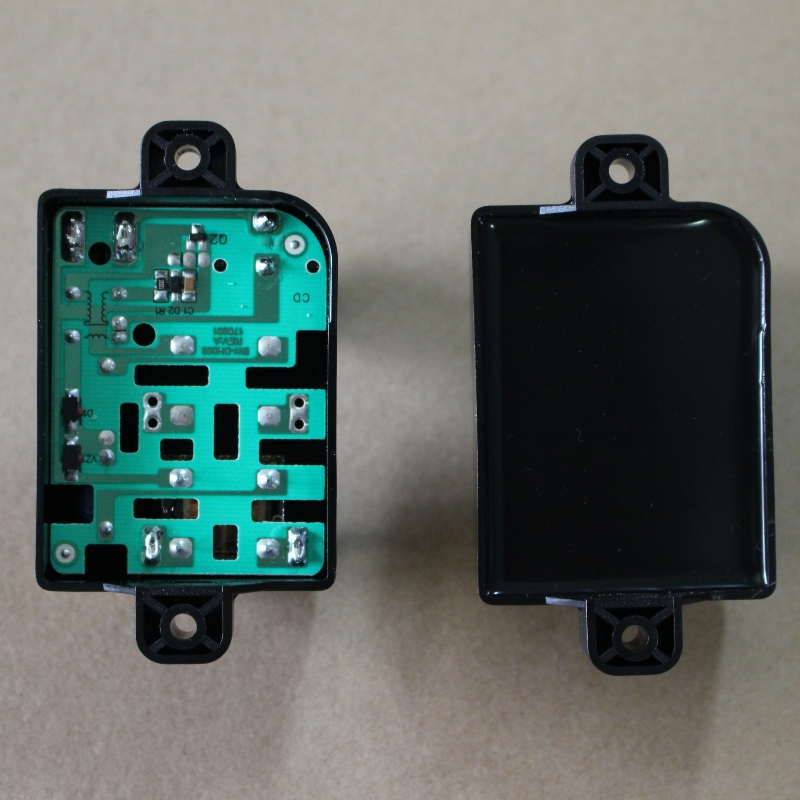

- It has excellent impact resistance and weather resistance. It is suitable for insulation, packaging and protection of electronic components.

- It is characterized by low hardness, moderate strength, good elasticity, water resistance, mould proof, shock proof and transparent.

- It has excellent electrical insulation and fire resistance.

- It has good adhesion to steel, aluminum, copper, tin, rubber, plastic and wood materials.

- The potting materials can make the installed and debugged electronic components and circuits free from vibration, corrosion, moisture and dust.

Product Details

1. Introduction:

FM-500 (6) - 12 is a two-component polyurethane sealant with excellent electrical properties, impact resistance and weather resistance. It is suitable for insulation, packaging and protection of electronic components.

2.General performance:

Test items: test method or condition: 500 (6) - 12a 500 (6) - 12b

Visual inspection brown liquid black liquid

Viscosity: MPa. S 50 ± 30 9000 ± 2000

The density was 1.05 ± 0.05 1.30 ± 0.05

Storage life: room temperature sealed for 6 months to 6 months

3. Process performance:

Project unit or condition a / b

Mixing ratio: 30:100 by weight

Mixed viscosity: MPa. S 1000 ± 300

Operating time: min (160g, 100000 MPa. S) 20-40

Ripening conditions: HR 48 ~ 72

4. Properties after curing:

Project unit or condition 500 (6) - 12a / b

The hardness was 75 ± 10

The volume resistivity is Ω· cm > 4.0 × 1013

Insulation strength kV / mm > 20

Dielectric constant: 1MHz 5.0

Water absorption% < 0.3

Flame retardant grade: UL-94 V-0

Tensile strength MPa ≥ 20

Elongation% ≥ 10

Application temperature range ℃ - 40 ~ 135

5. Recommended process:

Manual glue pouring operation process:

1. Preheating: the casting device should be dried at 70-80 ℃ for 1-2 hours. The temperature can also be reduced and the heating time can be extended to remove moisture. The viscosity of material B will be higher at low temperature, and material a is easy to crystallize. Please preheat the material to 25 ~ 45 ℃ for easy use.

2. Mixing: weigh materials a and B according to the proportion. When mixing, mix vertically with the mixing rod and stir clockwise (or anticlockwise) in the same direction for 2-3 minutes. Try to reduce the amount of air mixed in. Pay attention to the bottom and edge of the container to mix evenly, otherwise there will be local non curing phenomenon.

3. Defoaming: if the pouring surface is required to be smooth and smooth without bubbles, the mixture should be vacuumized (≤ - 0.1MPa) to remove bubbles smoothly. If mechanical metering is used for mixed potting, steps 2 and 3 are omitted.

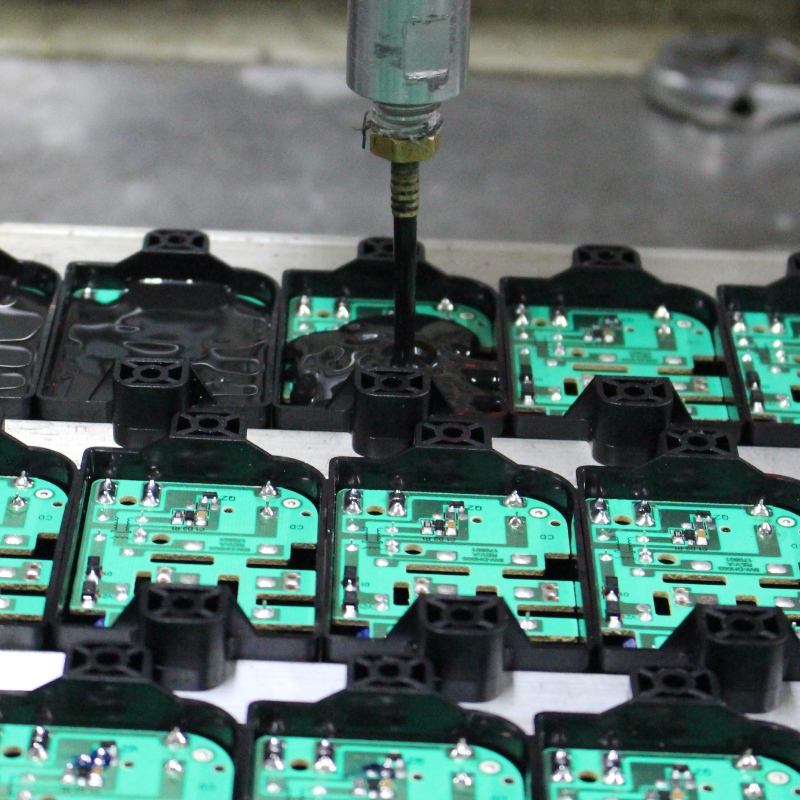

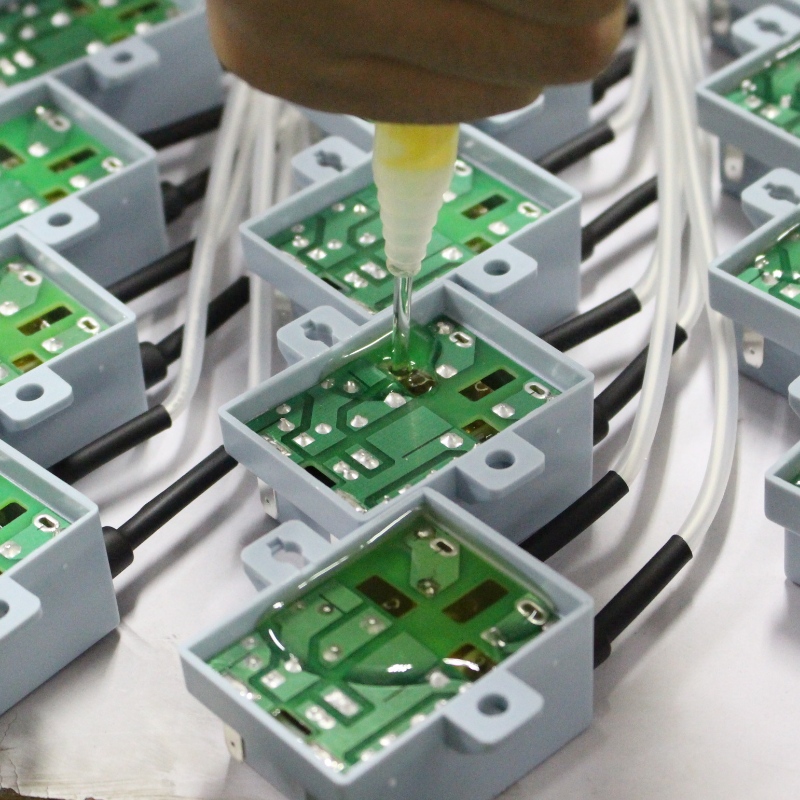

4. Pouring: the mixture is poured into the device. If the device structure is complex and the volume is large, it should be poured in stages. The pouring bubbles can be blown by hot air gun to eliminate the surface floating bubbles.

5. Curing: it can be cured at 3 ~ 4hr / 23 ℃ and fully matured at 48 ~ 72hr / 23 ℃. If the temperature is low, the curing time should be prolonged as appropriate. This product is sensitive to moisture, which will cause curing bubbles. It is recommended to control the operating environment at 23 ± 3 ℃ and relative humidity < 70%.

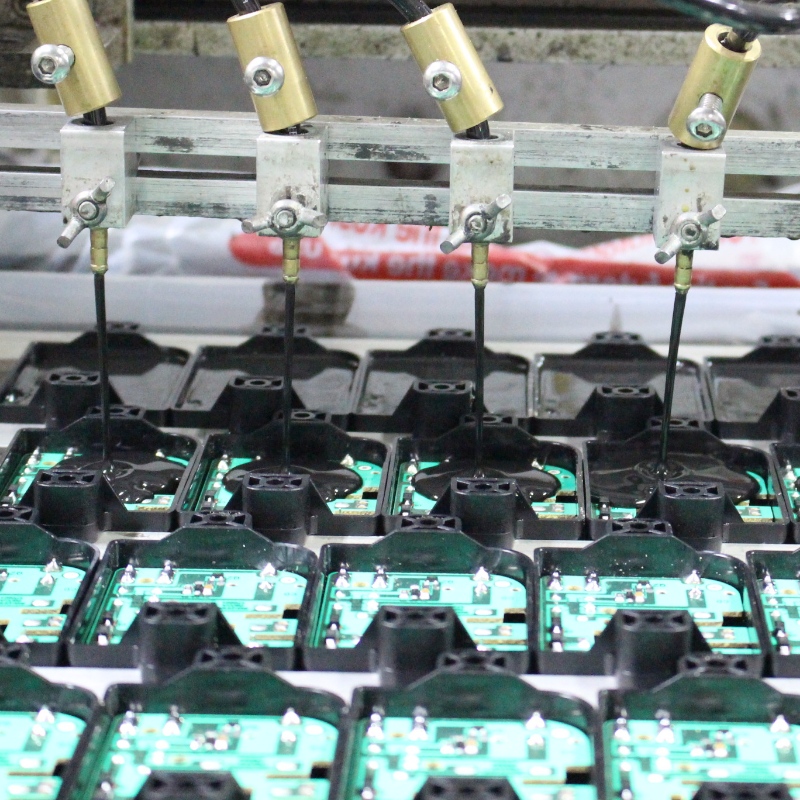

Machine glue filling operation process:

1. Preheating: the casting device should be dried at 70-80 ℃ for 1-2 hours. The temperature can also be reduced and the heating time can be extended to remove moisture. The viscosity of material B will be higher at low temperature, and material a is easy to crystallize. Please preheat the material to 25 ~ 45 ℃ for easy use.

2. Mixing: the machine mixes automatically. However, before using the machine every day, it is necessary to measure whether the mixing ratio of a and B materials meets the specified mixing ratio.

6. Defoaming: the filling process is carried out in the fully closed state of the machine pipe, and the mixture does not need to be defoaming.

7. Pouring: the mixture is poured into the device. If the device structure is complex and the volume is large, it should be poured in stages. The pouring bubbles can be blown by hot air gun to eliminate the surface floating bubbles.

8. Curing: it can be cured at 3 ~ 4hr / 23 ℃ and fully matured at 48 ~ 72hr / 23 ℃. If the temperature is low, the curing time should be prolonged as appropriate. This product is sensitive to moisture, which will cause curing bubbles. It is recommended to control the operating environment at 23 ± 3 ℃ and relative humidity < 70%.

(when filling and sealing the machine, please operate according to the machine manual)

6. Storage, transportation and precautions:

1. Store at room temperature (5 ~ 35 ℃) and humidity (45 ~ 80% RH), dark and sealed.

2. Component B may have a small amount of precipitation after long-term storage. Please stir well before use.

3. Please check the product model and weigh accurately.

4. After opening the package of materials a and B, they should be used as soon as possible. If they can not be used up, they should be sealed and stored immediately to avoid moisture.

5. If the machine is used for glue filling, it is recommended to clean the mixing chamber and head of the machine every day.

6. This kind of product belongs to non dangerous goods and is stored and transported as general chemicals.

7.Package specification:

Package of material a: 20kg iron drum

Package of material B: 25kg iron drum

Note: the above performance data is the typical data of the product after curing at 23 ℃ and 60% humidity. It is only for reference when the product is used by customers. It can not guarantee all the data that can be achieved in a specific environment. Before using, customers must make necessary test confirmation to make the product suitable for your process or use. The reliability of the product depends on both of us. We reserve the right to modify the above data. Please use this product according to the measured data.

Dongguan fuming sealing material Co., Ltd

Contact Person: Lu Yanting

Department: Marketing Department

Post: manager

Landline: +86 0769-85235661

Company Address: Nanzha No.4 Industrial Park, Humen Town, Dongguan City, Guangdong Province

Factory Address: Nanzha No.4 Industrial Park, Humen Town, Dongguan City, Guangdong Province

Website: fuming.us764.com

Previous: No